LXR Devlog #3 - Building the Mammoth!

Baseline case.

Greetings, INNOvators!

The journey towards reimagining computing continues with the birth of the "Mammoth."

This 3D-printed chunky case marks a significant milestone in the development of the LXR project.

The Mammoth: An Overview

The Mammoth is a two-part case designed to house the essential components of the LXR project. Let's break down its key features:

Components

Split Ergonomic Keyboard (on top of each part of the case)

Single Board Computer (inside the left part of the case)

Battery (inside the right part of the case)

Design Considerations

Modularity: The two-part design allows for easy access to individual components, enhancing maintenance and flexibility.

Just make it fit: The goal being to setup a baseline that we can iterate on, the modelling was pretty basic and didn’t try to be clever or optimise anything, it should just work.

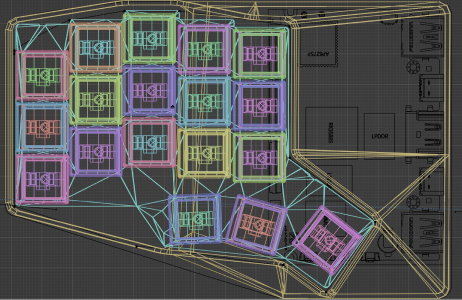

We jumped onto Blender to get a quick first overview then once it was good enough we printed it!

Printing the Mammoth with standard PLA.

For printing, we use the Bambu Lab X1, which is an excellent 3D printer (https://eu.store.bambulab.com/fr-fr/products/x1-carbon-combo).

First contact with the Mammoth

Upon assembling the Mammoth, it became clear that this design despite being pretty rough, represented a significant leap forward in comparison with classic laptops.

It’s alive!

We tested it… and it was fun!

Here is a sneak peek:

Lessons Learned

While the Mammoth prototype successfully demonstrated the feasibility of this concept, it also highlighted areas for refinement:

Optimisation Opportunities: Further iterations will focus on fine-tuning component placement for enhanced efficiency (and find a battery that fits)

Material Selection: Exploring materials with improved durability and weight characteristics is a priority (PLA is not made for this)

What's Next?

With the Mammoth as our foundation, the path forward involves meticulous optimisation and refinement.

Stay tuned for the next Devlog as we delve deeper into component selection and fine-tuning!

Until then, keep INNOvating!